Climatech supplies high-quality products to our worldwide customer base at competitive prices. We strive to provide service and support to exceed customer expectations, and we have multiple locations to serve a diverse market. We have a long history of providing our products to companies, both big and small, across a variety of industries.

Headquarters – Eden Prairie, MN

At our corporate location in Eden Prairie, MN, our facility boasts 92,000 sq. ft. of manufacturing and office space for designing products for companies across the globe. Here, you’ll find the following core departments:

- Extrusion

- Fabrication

- Molded Components

- Sealing Solutions

- Structural Components

- Sales

- Engineering

- Quality

- Accounting

- Human Resources

Southwest Operation — Phoenix, AZ

Our Southwest Operation is located in Phoenix, AZ, and it’s equipped with over 24,000 sq. ft. of manufacturing and office space. At our Southwest Operation, you’ll find the following core departments:

- Extrusion

- Fabrication

- Molded Components

- Sealing Solutions

- Structural Components

- Sales

- Quality

Mexico Operation — Monterrey, MX

Fill with information about MX. 55,000 sq. ft.

- Fabrication

- Molded Components

- Sealing Solutions

- Sales

- Quality

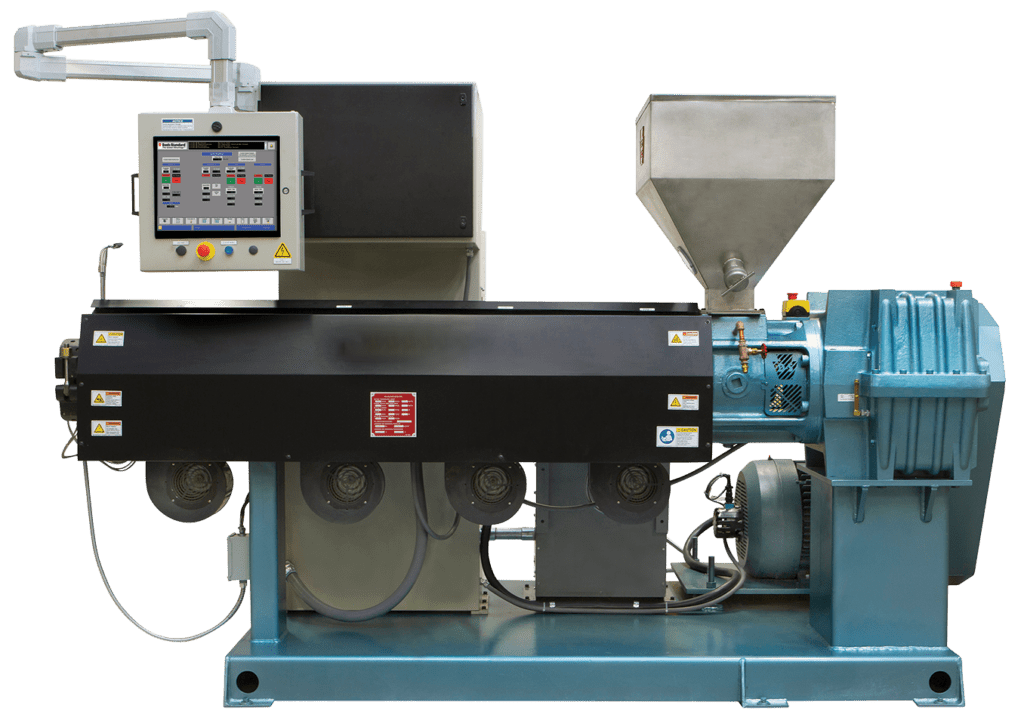

Extrusion

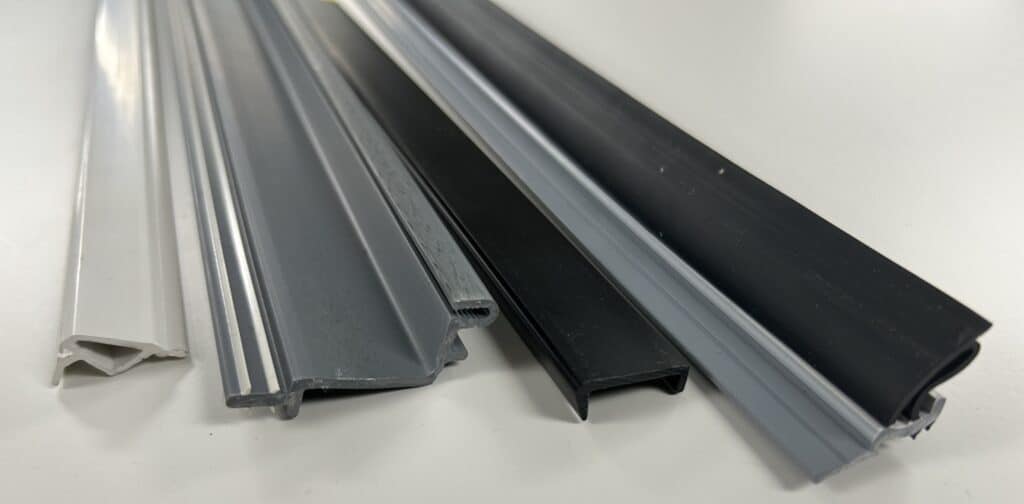

Climatech is an industry-leading provider of plastic profile extrusions. Equipped with multiple extrusion lines and an in-house tooling shop, our team can produce custom profiles in various sizes from a variety of materials to suit different uses and environments.

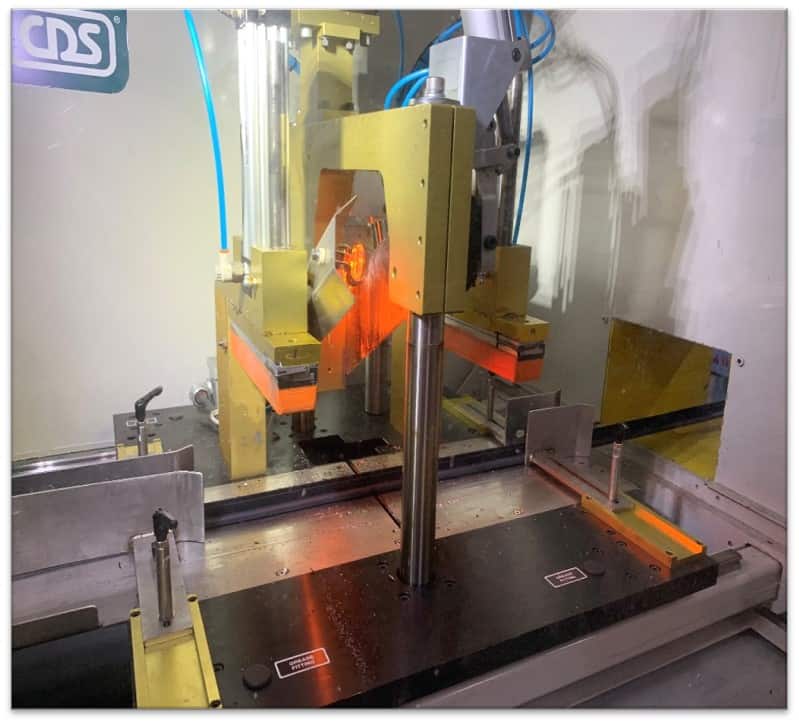

Our company houses 16 main extrusion lines with barrels that are 2 1/2, 3 1/2, and 4 1/2 in. in diameter and co-extruders with barrels that are ¾ in. and up in diameter. The lines incorporate a variety of post-extrusion equipment, including cooling systems, pullers, and cutters, which aid in the production of high-quality extruded components.

We also have an in-house tooling facility with a full machine shop, wire EDM units, and CNC equipment. It allows us to produce custom tooling with typical lead times of six to eight weeks.

Extrusion Processing

Our extrusion department has a number of extrusion lines giving us flexibility to make parts as small as 1/4″ and up to 9″+ while varying shape and material.

Extrusion

With 15+ main extrusion lines throughout the company we can process a mix of materials to multiple shapes meeting your production requirements.

Co-Extrusion

Utilizing smaller extrusion machines we have the capability to co, tri or quad extrude materials allowing a mix of rigids, flexibles and cap to create the ideal part for application.

Cooling

The extrusion process requires heat but cooling is arguably more important to shape and create parts. We use various cooling methods to meet tolerance requirements and create consistency in extruded components.

Air

Water

Vacuum

Cutting

We have the capability to cut long lengths, short lengths, tight tolerance or rough tolerance.

Saws

Blades

Knife

Value Added Services

Does your extrusion need more once it comes off the line? Our value added services can finish a lineal extrusion and have it turn key for your operation.

- Drilling

- Punching

- Close Tolerance Cutting

- Embossing

- Printing

- Secondary Material – Tape/Adhesive

Engineering Support

Dedicated engineering team to assist with your application needs. Providing material guidance, part manufacturability suggestions or continuous improvement on our manufacturing floor.

Labeling

Custom labeling for warehousing, tracking and quality control.

Packaging

Climatech can create custom packaging, use returnable packaging or work with your needs to make sure product arrives efficiently.

Logistical Support

Need to limit your inventory? Our team can manage inventories, ship to forecasts and deliver just in time.

Prototyping

Climatech can create rapid prototypes without the need for full production ready tooling.

Extrusion Solutions With Climatech

At Climatech, we put the customer first. That’s why we work to provide the best possible solutions. By partnering with us for their extrusion needs, they benefit from our:

- Short lead times: Our standard lead times are six to eight weeks for tooling and three to four weeks for production, but we can meet shorter lead time requirements if needed.

- Competitive prices: Our team helps customers identify the best-priced solution for their projects.

- High quality standards: Our quality management is ISO 9001:2015 certified, so customers can trust that they are getting high-quality extruded components. Our testing and inspection equipment includes check gauges, visual mylar overlays, calipers, tape measures, optical comparators, smart scopes, and more.

- In-house tooling capabilities: Our in-house tooling facility makes it easy for us to quickly accommodate projects that require custom tooling.

- Flexible production capacities: Our team can handle orders for production volumes ranging from medium to large.

- Tight tolerances: We can meet various tolerance requests, depending on the extrusion’s material and size.

We process a wide range of plastic materials within our extrusion division. We commonly work with the following:

Rigid Materials

Rigid

- ABS

- ASA

- HIPS

- Polypropylene

- PVC

- CPVC

- Special Composite Polymer (SCP)

Flexible

- Alcryn®

- EVA

- TPO

- TPE

- TPV

- PVC

- Santoprene™

- Urethane

Other

- Additives

- Anti-fungal

- Anti-mildew

- Anti-static

- Cap Stock

- Colorants

Industries and Applications Served

Our extrusions primarily find application in the window and door, appliances, and mineral processing, markets but our extrusion team can work with customers from any market.

To learn more about our extrusion capabilities or discuss your extrusion needs with one of our team members, contact us today.

Fabrication

Climatech is a premier provider of custom fabrication solutions. We offer a broad selection of fabrication services, including die cutting, converting, CNC fabricating, laminating, kitting, and more. Armed with extensive experience, cutting-edge equipment, and multiple types of tooling, our team can handle virtually any flexible substrate and turn it into a variety of parts and products. We produce components ranging from simple die-cut gaskets to specialized assemblies with tight tolerances in short or long runs.

Our Fabrication Services

Our fabrication department has the equipment and the processes needed to take raw or semi-finished materials and turn them into finished components meeting your specifications.

- Laminating

- Slitting

- Die Cutting

- Rapid Prototyping

- CNC Fabrication

- Kitting

- Engineering Support

Engineering Support

Dedicated engineering team to assist with your application needs. Providing material guidance, part manufacturability suggestions or continuous improvement on our manufacturing floor.

Labeling

Custom labeling for warehousing, tracking and quality control.

Packaging

Climatech can create custom packaging, use returnable packaging or work with your needs to make sure product arrives efficiently.

Logistical Support

Need to limit your inventory? Our team can manage inventories, ship to forecasts and deliver just in time.

Prototyping

Climatech can create rapid prototypes without the need for full production ready tooling.

Equipment

Our facility houses a range of fabrication equipment, allowing us to accommodate all of our customers’ fabrication needs. Our equipment list includes:

- CNC Saws

- Slitters

- Laminators

- CNC Routers

- CNC Flash Cutters

- Small, Medium, and Large tonnage presses

- Computer-controlled die cutters

- Rotary die cutters

- Rapid prototyping machines and tools

Converting

Our ability to convert non-metallic materials in-house creates a controlled environment giving us the flexibility to customize and combine raw materials to meet specific application needs. Our team completes multiple converting operations for internal production and external customer needs.

Laminating

If a custom adhesive is needed or if two materials need to be bonded together our team can create the multi-layered solution for your application.

Slitting/Splitting

Custom thickness or widths required? Expertise in slitting and splitting allows us to match your application!

Die-Less CNC Fabrication

Programmed with a CAD model our CNC cutting equipment doesn’t need a die allowing us the flexibility to prototype or full-scale produce without the upfront costs for the customer.

CNC Router

Programmable bit cutting for rigid materials.

CNC Flash Cutter

Programmable knife cutting for flexible materials.

Die-Cutting

Using steel rule and/or hard tool dies we can produce tight tolerance non-metallic parts for a wide range of volumes.

Computer-Controlled Die-Cutting

Automated Die-Cutting

Fabrication Solutions With Climatech

At Climatech, we strive to deliver top-quality solutions to our customers. By choosing us for their fabrication needs, they benefit from our:

- Fast turnaround: We offer standard lead times of one to three weeks for tooling and three to four weeks for production. However, we can achieve faster turnaround if needed.

- Competitive prices: We can present customers with options for better pricing than our competitors.

- High quality standards: We maintain ISO 9001 certification and can produce components to automotive or Mil-spec standards.

- Robust inspection methods: We perform a variety of tests on our fabricated components using check gauges, visual mylar overlays, and calibers and tape measures.

- Rapid prototyping services: We can quickly produce prototypes for proof of concept and testing.

- Flexible production capacities: We can accommodate small to large volume orders.

- Tight tolerance capabilities: We can meet various tolerances requests, depending on component material and size.

We use all types of substrates & adhesives in our fabrication projects, including, but not limited to the following:

Fabrication Materials

- Blended Sponge

- EPDM

- Filter Foam

- High-Heat Melamine

- Neoprene

- Polyester

- Polyethylene

- PVC

- Silicone Sponge

- XLPE

- High Density Polyethylene

- Low Density Polyethylene

- Linear Low Density Polyethylene

- Ultra High Molecular Weight Materials

- Composites

- Cork

- Felt

- Graphite

- High Temperature Insulation

- Thin Gauge Foils

- Pressure-Sensitive Adhesives

Our Partners in the Industry

Industries and Applications Served

Our fabrication team can work with customers from any market. However, we often serve those looking for components for appliances, general industrial devices and systems, or recreational vehicles

Typical parts and products we produce include:

- Seals

- Gaskets

- Belting

- Vibration dampeners

- Isolation devices

- Heat/electrical insulation

- Noise reducers

- Custom Packaging

To learn more about our fabrication capabilities or discuss your fabrication needs with one of our team members, contact us today.

Molded Components

Applications

- Compression Molded Floor Mats

- Intake Ducts

- Grommets

- Vibration/Isolation Dampers

- Storage Liners

- Fuel Cap Covers

- Brackets

Services

Engineering Support

Dedicated engineering team to assist with your application needs. Providing material guidance, part manufacturability suggestions or continuous improvement on our manufacturing floor.

Labeling

Custom labeling for warehousing, tracking and quality control.

Packaging

Climatech can create custom packaging, use returnable packaging or work with your needs to make sure product arrives efficiently.

Logistical Support

Need to limit your inventory? Our team can manage inventories, ship to forecasts and deliver just in time.

Prototyping

Climatech can create rapid prototypes without the need for full production ready tooling.

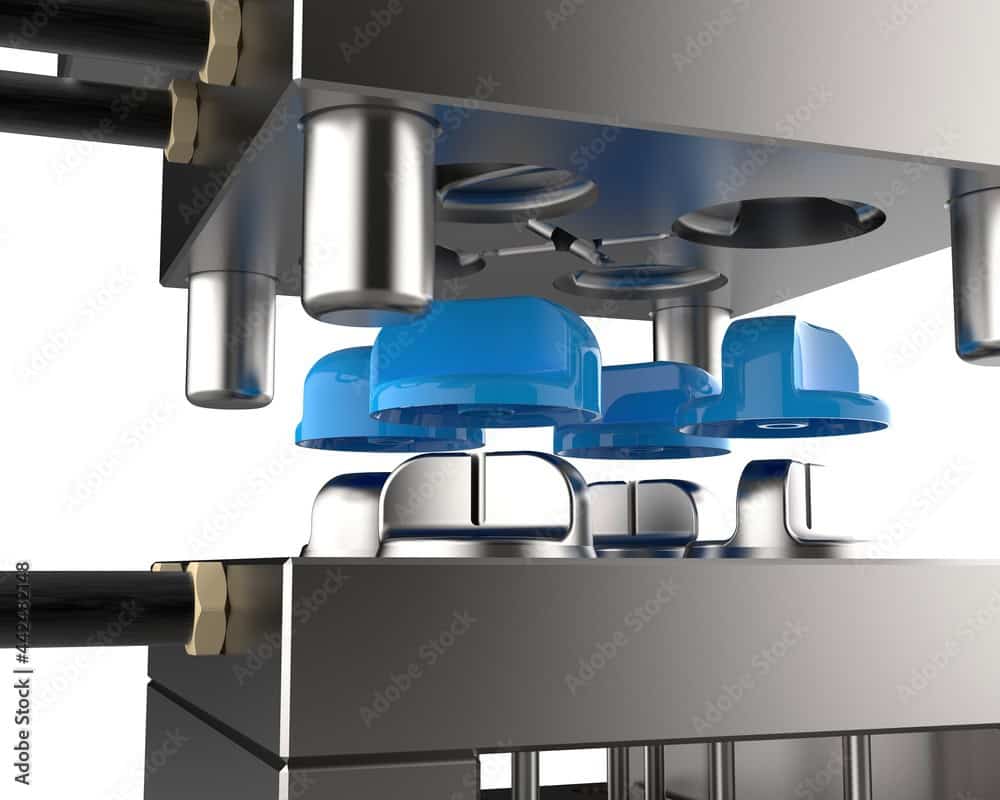

Molded Rubber

- Rubber Compression and Injection Molding

- Rubber Transfer Molding

- Cast Polyurethane Molds

- Rubber to Metal Bonded Molding

- Jigs and Fixtures

- Sub-Assemblies

- 20-1200 Ton Molding Machines

- 30-90 Durometer Shore A

Polymers

- Natural Rubber (NR)

- Polybutadiene Rubber (PBR)

- Styrene Butadiene Rubber (SBR)

- Nitrile Butadiene Rubber (NBR)

- Ethylene Propylene Diene Monomer (EPDM)

- Chloroprene Rubber (CR)

- Fluro Vinyl Methyl Silicone Rubber (FVMQ)

- Butyl Rubber (IR)

- Polyurethane Rubber (PU)

- Vinyl Methyl Silicone (VMQ)

- Fluorocarbon Rubber (FKM)

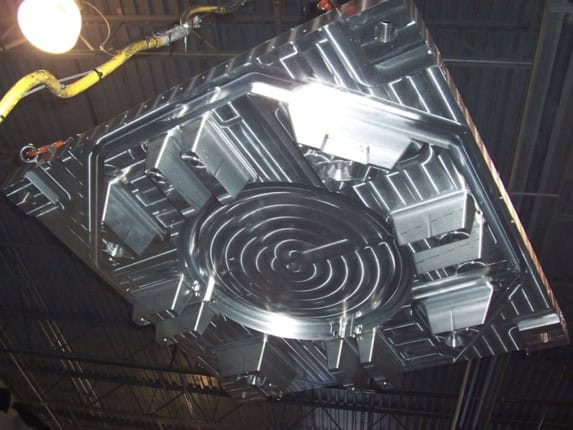

Molded Plastic

Capabilities

- Mold Sizes Up To 600mm X 1600mm (23.6″ X 63.0″)

- 75-1000 Ton Machines

- High Cavitation Molding

- Sub-Assemblies

- Internally Lubricated Resins (Bushings, Bearings, and High Wear Components)

- Over-molded Components

- Rapid Tooling and Prototyping

Resins

- Nylon (High Impact)

- Polypropylene

- HDPE

- ABS

- HIPS (High Impact Polystyrene)

- TPE/TPV

- Glass Filled and Mineral Filled Resins

Recycled Pallets

- Base Material: High Density Polyethylene

- Other Materials Used As Joiners For Flow And Strength

- RFID Tag Tracking Available

- Longevity/Lifetime Cost

- Cost Savings Through Re-Usability

- Lighter Weight, Reducing Freight Costs

- No Wood Treatment Requirements For International Shipments

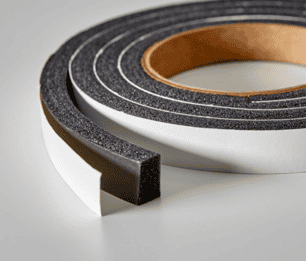

Sealing Solutions

Sealing

Nitrile Butadiene Gaskets

PVC Foam

Semi-closed Cell Foam

SF0

Fill large and varying gaps

Polyurethane foam

Low compression set

Silicone foam and rubber

High temperature

Low compression set

Low toxicity

Rubber and Sponge Extrusion

- Rubber Co-Extrusion

- Dense and Sponge Rubber

- Dual Durometer Seals

- Rubber Co-Extrusion

Adhesives

Acrylic PSA

3M™ VHB

3M™ Heat Activated Tape (ST1200, WT4112, 5933)

Extreme Sealing Tape

Services

Engineering Support

Dedicated engineering team to assist with your application needs. Providing material guidance, part manufacturability suggestions or continuous improvement on our manufacturing floor.

Labeling

Custom labeling for warehousing, tracking and quality control.

Packaging

Climatech can create custom packaging, use returnable packaging or work with your needs to make sure product arrives efficiently.

Logistical Support

Need to limit your inventory? Our team can manage inventories, ship to forecasts and deliver just in time.

Prototyping

Climatech can create rapid prototypes without the need for full production ready tooling.

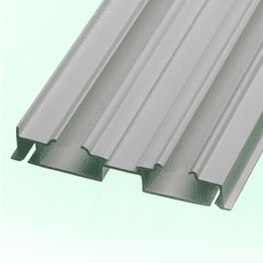

Structural Composites

Pultruded Fiberglass Components

- High Strength

- Beams, Grating, and Handrails

- Lightweight

- 75% less than steel

- 70% less than aluminum

- Corrosion Resistant

- Maintenance-Free

Services

Engineering Support

Dedicated engineering team to assist with your application needs. Providing material guidance, part manufacturability suggestions or continuous improvement on our manufacturing floor.

Labeling

Custom labeling for warehousing, tracking and quality control.

Packaging

Climatech can create custom packaging, use returnable packaging or work with your needs to make sure product arrives efficiently.

Logistical Support

Need to limit your inventory? Our team can manage inventories, ship to forecasts and deliver just in time.

Prototyping

Climatech can create rapid prototypes without the need for full production ready tooling.